The drying characteristics of wet solids is best. Before starting your submission please check that this journal.

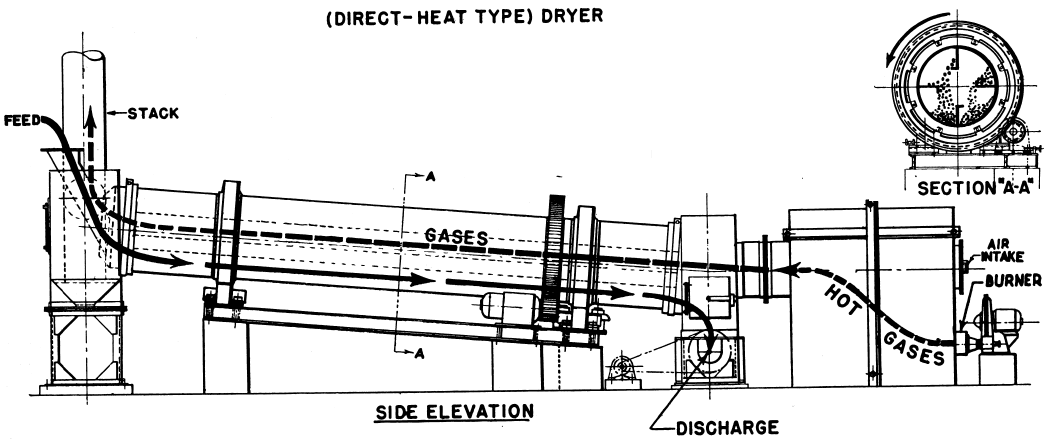

Rotary Dryer Design Working Principle

They are inherently cocurrent dryers with the hottest air contacting the wettest product.

. Home All Journals Drying Technology List of Issues Volume 9 Issue 5 DRYER CALCULATIONS Search in. Of the numerical calculations were partially compared. The Design of Spin Flash Dryer JIANG BinCHAI Ben-yinPENG Li-hua MIAO ShuaiDONG Xian-huaZHANG Lei Shandong Tianli Drying Equipment CoLtdJinan 250014China This paper introduces structure drying principles of Spin Flash Dryer and calculation and determination of related parameters.

60 kg of wet product contains 60 x 055 kg water 33 kg moisture and. Process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior. Capacity based on 10 moisture wet weight in material fed to dryer and 326 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder.

This process is one of the simplest unit operationsIf the throttling valve or device is located at the entry into a pressure vessel so that the flash evaporation occurs within the. ROTARY DRYERS Tedrow Steam Design. Shell Installation Geometry Module.

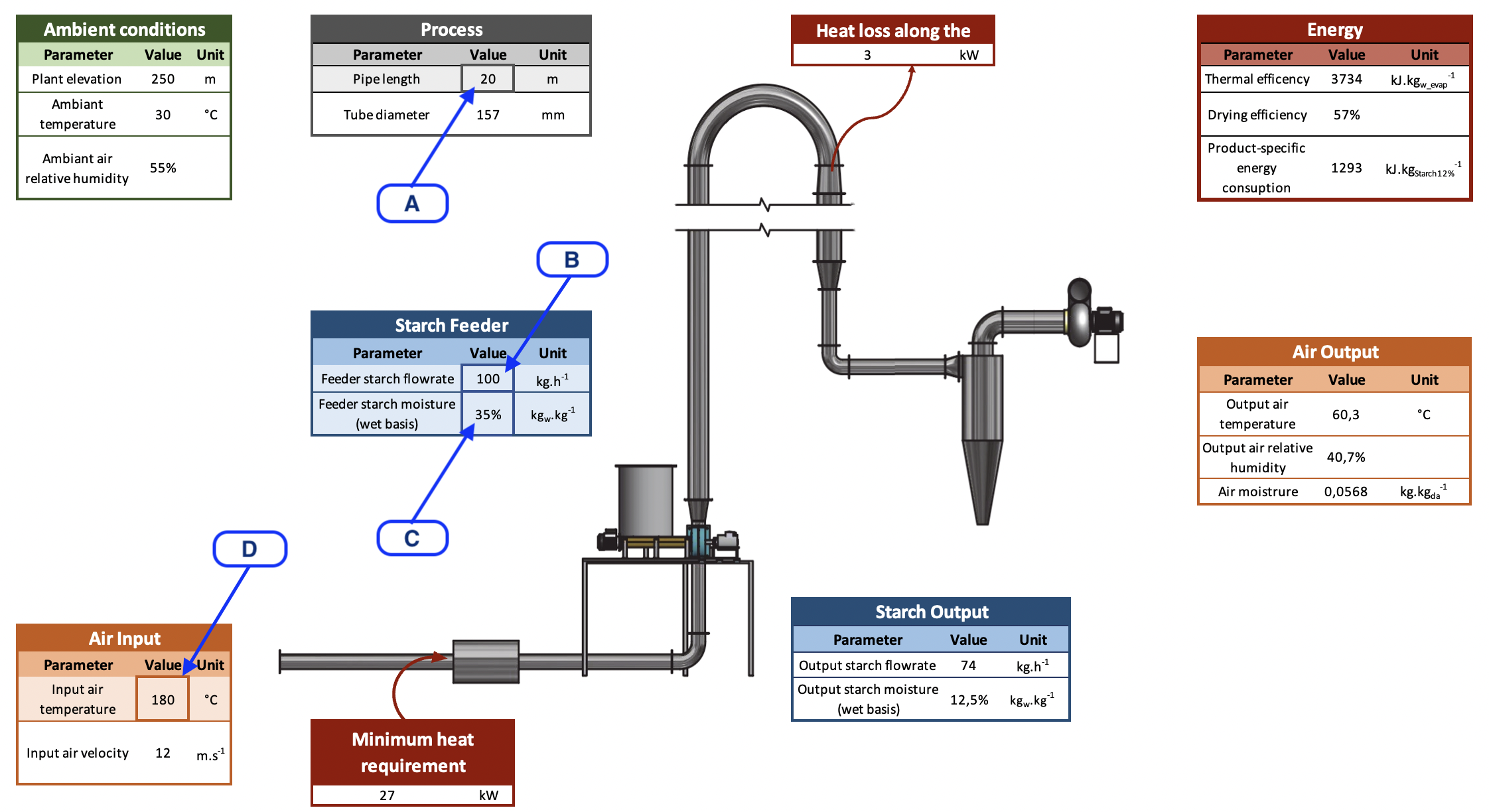

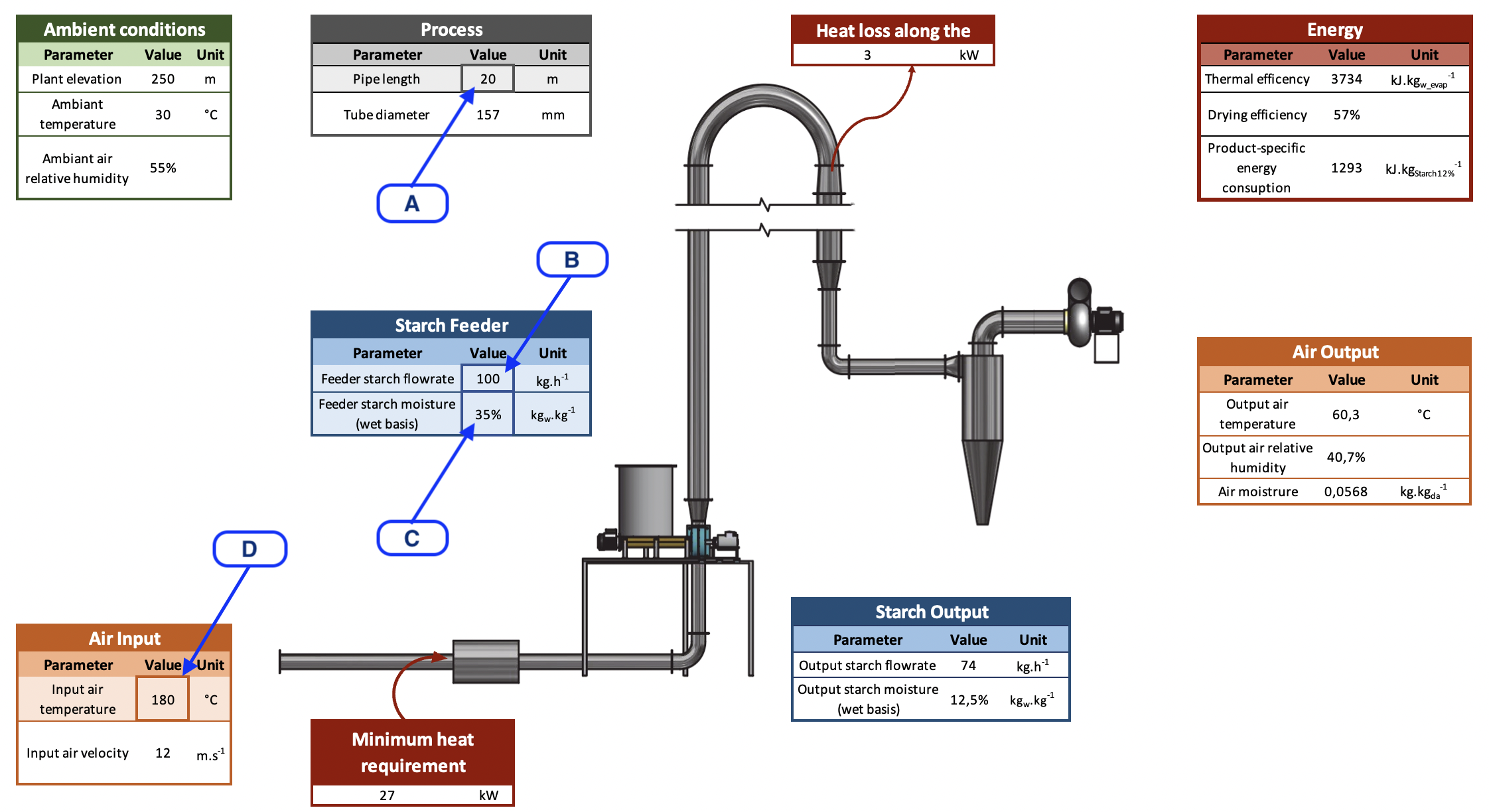

The design of agitated thin film dryer ATFD is difficult both mechanically and process engineering point of view. Design basis The following were the physico-chemical properties of cassava starch used as input variables to determine parameters of interest necessary for the design of a column flash drying unit. The effect of flow rate jacket side heating medium temperature and speed of the rotor.

The present work describes the basic flow pattern in ATFD in terms of bow wave and its transformation along the dryer height. Microsoft PowerPoint - Flash Design Compatibility Mode Author. With experimental data and the influence of the fric-tion factor on the pressure gas and particle.

9162013 60853 PM. 3 Additional energy demands. As per theory thickness can be derived using the formula T P x R S x E - 06 x P P - design pressure R - Inner dia S - allowable stress E - Joint efficiency.

The spray dryer usually has a greater amount of water to remove by thermal methods than other types. A dr 11982777 200 245 - 80 241 001 200 463 - 80 045 39565 kgh. 2 Thermal inefficiencies in the utility heat supply system.

Flash drying is a continuous process with the dryer being either directly or indirectly fired. Provided Rotary Dryer dimensionφ2020m. A material moisture content solid line and.

The results prove that the dryer is most efficient when the dryer runs at 370 Kelvin and 03 meters per second when the allotted drying time is less than 217 hours. 163 Design of Flash Dryers. Calculation of the quantity of water to be evaporated is explained below with a sample calculation.

Design calculations establish minimum guidelines and requirements for generating electrical calculations on projects. Feed moisture content 6875 wet basis Carbohydrate content of cassava starch 2890 Protein content of cassava starch 175. 1 Thermal inefficiencies in the dryer.

60 kg of wet product contains 60 x 055 kg water 33 kg moisture and. Let the design pressure be 30 excess to the working pressure P. Flash evaporation or partial evaporation is the partial vapor that occurs when a saturated liquid stream undergoes a reduction in pressure by passing through a throttling valve or other throttling device.

Steam generation efficiency steam leaks and mains losses. Flash Dryer Design Calculations. The customer furnishes and erects the brickwork setting for the dryer in accordance with drawings furnished by Equipment Company.

The design of agitated thin film dryer ATFD is difficult both mechanically and process engineering point of view. They operate at inlet temperatures varying from ambient dehumidified air for sensitive products to more than 1100 o F 600 o C for robust products. Rotary Dryer Calculation Volume calculation.

Selected dryer type so the set of design param-eters or assumptions is fulfilledthis is the com-mon design problem. An allotted drying time between 217 and 254 hours would require a drying air temperature between 290 and 293 Kelvin and a drying air velocity of 03 meters per second. Skip to Main Content.

FLASH DRUM DESIGN ChE 4253 - Design I Calculations to make Ratchford Rice Equation look for it F LV Fz Lx Vy ii i yKx iii i 1 i. Exhaust heat content in convective dryers sensible heating of solids heat losses from dryer body. The above calculation can be simplified by neglecting the air moisture content and powder moisture and using for heat capacities of air and of water vapour.

Log in Register Cart. FIGURE 39 Longitudinal parameter distribution for a cross-flow dryer with one-dimensional solid flow. For example to dry 20000 lbshr 9000 kgh of a 30 solidswater slurry to 05 moisture the spray dryer would have an approximate diameter of 30 ft.

Flash drying is a continuous process with the dryer being either directly or indirectly fired. Design calculations may be made either manually or by SPU-approved computer programs. Let the working pressure be 25 Kgcm2 Vacuum.

The version installed for this particular process utilizes a feed. Ad Get Flash Dryers Equipment Within 24 Hours Or Consult With Industry Experts. If the throughput of the dryer is 60 kg of wet product per hour drying it from 55 moisture to 10 moisture the heat requirement is.

Were pleased that you plan to submit your article. Electrical calculations should be made for all SPU projects that include electrical components and should be filed in the project notebook. The present work describes the basic flow pattern in ATFD in terms of bow wave and its transformation along the dryer height.

The effect of flow rate jacket side heating medium temperature and speed of the rotor has been studied. Power for solids transport vacuum pumps and air fans.

Diagram Of A Flash Dryer For Pulp According To Svensson 51 Download Scientific Diagram

Flash Dryer Design Tools Rtb Scaling Flash Drying

Pdf 6 Pneumatic And Flash Drying

Pdf 6 Pneumatic And Flash Drying

Pdf 6 Pneumatic And Flash Drying

0 comments

Post a Comment